RepRap

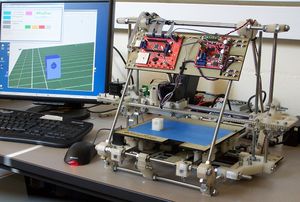

RepRap is a free desktop 3D printer capable of printing plastic objects. Since many parts of RepRap are made from plastic and RepRap can print those parts, RepRap can be considered a self-replicating machine - one that anyone can build given time and materials. It also means that - if you've got a RepRap - you can print lots of useful stuff, and you can print another RepRap for a friend...

Reprap.org is a community project, which means you are welcome to edit most pages on that site, or better yet, create new pages of your own. Their community portal and New Development pages have more information on how to get involved.

Contents

[hide]Versions

RepStrap

A RepStrap is a non-replicating kits that provide similar functionality to a RepRap.

- http://objects.reprap.org/wiki/FTIStrap

- http://www.teeter.com/Construction_of_my_Repstrap_3d_printer-2.html

- http://reprap.org/wiki/Builders/Frank

- http://reprap.org/wiki/McWire_Cartesian_Bot_1_2

- http://objects.reprap.org/wiki/Hydra-MMM_Prototype

- http://objects.reprap.org/wiki/Isaac

- http://objects.reprap.org/wiki/LeBigRep

Darwin

Mendel

Mendel Specifications

The table below outlines the specifications of the machine.

| Metric | US imperial | |

|---|---|---|

| Manufacturer | RepRap (or anyone who wants...) | |

| Model | Mendel | |

| Technology | FFF (Fused Filament Fabrication)/Thermoplastic extrusion | |

| Price of all materials | €350 | $520 |

| Annual Service Cost | Occasional oiling = €5. It can print its own replacement printed parts at material cost. | Occasional oiling = $8. It can print its own replacement printed parts at material cost. |

| Size | 500 mm (W) x 400 mm (D) x 360 mm (H) | 20” (W) x 16” (D) x 14” (H) |

| Weight | 7.0 kg | 15.5 pounds |

| Build Envelope | 200 mm (W) x 200 mm (D) x 140 mm (H) | 8” (W) x 8” (D) x 5.5” (H) |

| Materials | PLA, HDPE, ABS & more. Uses ø 3 mm filament. | PLA, HDPE, ABS & more. Uses ø 1/8” filament. |

| Material Cost | PLA: €22/kg, HDPE: €11/kg, ABS: €17/kg | PLA: $14/lb, HDPE: $7/lb, ABS: $10/lb |

| Speed | 15.0 cm3 per hour solid (test done for PLA, similar for others) | 0.92 inch3 per hour solid (test done for PLA, similar for others) |

| Accuracy | Diameter of nozzle 0.5 mm, 2 mm min. feature size, 0.1 mm positioning accuracy, layer thickness 0.3 mm | Diameter of nozzle 0.020”, 0.080” min. feature size, 0.004" positioning accuracy, layer thickness 0.012” |

| Finish | Fair | |

| Volume of printed parts to replicate | 1110 cm3 | 67.7 inches3 |

(With the standard infill settings the 15.0 cm3 per hour solid extrusion rate is equivalent to a built volume rate of 19.0 cm3 per hour.)

Huxley

RepRap Version III "Huxley" is being developed on this and associated pages. It is based on Ed's original Mini-Mendel design, together with a lot of work already put in by others (ErikDeBruijn and others). Huxley is named, like all RepRaps, after a biologist: Thomas Henry Huxley.

To clarify, Huxley will be Mini-Mendel with some re-designed parts plus more documentation, defined integrated electronics (with alternatives, of course), and a selection of alternative firmware and host software configured to drive it. We will be integrating as much as possible of the work such as Brutis already done on Mini-Mendel.

The machine uses M6 threaded rods and M3 nuts and bolts (as opposed to the M8/M4 used on Mendel) and NEMA 14 Stepper Motors. The reprapped parts are about 30% of the volume of those for Mendel, which is to say it could reproduce three times faster.

Mendel can print itself, and so will Huxley. In addition, Mendel will be able to print Huxley, and Huxley will be able to print Mendel. We will continue Mendel development to turn it into a multi-material machine. Huxely will be a one-material machine, though we will probably also add a Pen Plotter so we can write etch-resist on PCBs and use an Oil Pen to facilitate separation of Support Material for overhangs.

Mendel vs. Darwin

Mendel is the latest generation RepRap machine. Mendel supersedes the first version, which we call Darwin. For RepRap Version I "Darwin" instructions follow this link.

Mendel has the following key improvements over Darwin:

- Bigger print area, smaller machine footprint

- Improved constraint on the z-axis to eliminate jamming

- Better axis efficiency

- Simpler assembly

- Capacity for tool changing (to follow very shortly)

- Lighter and more portable